After a $600,000 research grant was awarded to Nome, Alaska, last year, top officials at the research center U.S. Department of Housing and Urban Development (HUD) visited the University of Alaska Fairbanks to promote the possibilities that 3D printing technology brings to the construction of affordable housing in the United States

The grant goes to a task force made up of Penn State partners and a nonprofit research firm Extreme Habitat Research Institute (XHI). The partners will perform the “design, engineering, materials research, development, planning and analysis” required for 3D printing to provide “high-quality, affordable, energy-efficient and sustainable housing for communities in subarctic Alaska,” HUD explained.

HUD Grants and Related Efforts

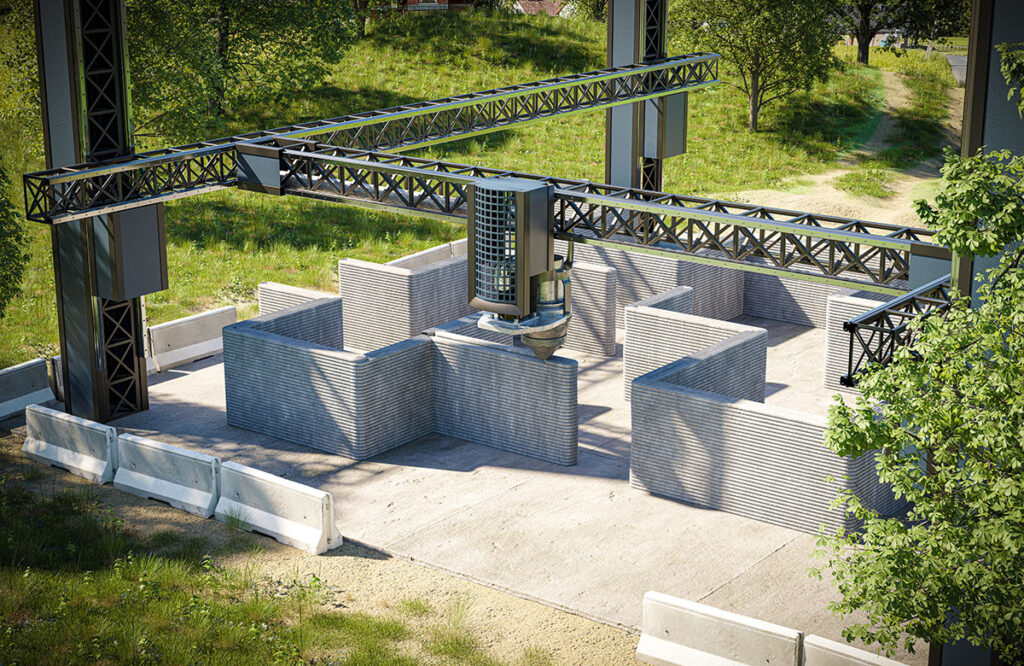

Penn State students will work on “refining, testing and designing protocols” for the mobile printing unit, the core of which will be transferred to the city of Nome. There, HUD explains, teams will build and evaluate prototype homes using “specialized 3D printers designed and built for the environment.”

A key goal of the project includes deploying local and sustainable building material resources. In addition to HUD, the university and the city of Nome, other partners include Alaska Housing Finance Corporationthis Cold Climate Housing Research Centerthis National Renewable Energy Laboratory, XHab 3D Company and Fairbanks Materials

This week, HUD officials – including Solomon Green, principal deputy assistant secretary for policy development and research (PDAS); Richard Monocchio, PDA for Public and Indian Housing; and Andrew Lofton, Northwest Territory Administrator ) demonstrated the new technology at an event.

“If we want to build the affordable housing of the future, we need to be bolder, bolder and more creative than ever before,” Green said in a statement. “At HUD, we’re using innovative solutions to build The housing our growing nation needs. This 3D printer is an exciting example of this new frontier and we can’t wait to see it in action.

Lofton said the demonstration marked a “big day”, adding that the use of new technology could have a significant impact on growing housing supply problems across the country, which are improving. This is especially true for areas with extreme climates such as Alaska.

“Today, we demonstrate the latest example of how technology innovation, combined with local knowledge and strong community partnerships, can help us build the high-quality, affordable and resilient homes our country needs,” Lofton said.

Cost and efficiency potential

Earlier this year, an article in Smithsonian Magazine took a closer look at the potential of 3D-printed homes. The opportunity is there, the article explains, as the technology outpaces traditional methods and costs start to fall.

serralomas, beneficiary habitat for humanity The article profiles her home in Newport News, Virginia, where she describes the “surreal” experience of watching a 3D printer print 166 individual layers of concrete to form the walls of her home.

“Concrete prints faster—the walls of a 1,300-square-foot house in Sierra were built in about 40 hours,” the article reads. “It’s also cheaper than traditional wood-frame construction, which has changed little in a century.”

Habitat for Humanity Peninsula and Greater Williamsburg Virginia Chapters have built three 3D printed homes in Virginia to date, with more on the way. The organization’s chief executive said the cost of each subsequent project has dropped.

“The cost of Habitat in Sierra is approximately $215,000, $25,000 less than the first project; the land is not under the jurisdiction of the city’s housing authority,” the article said.

The article adds that because concrete has better insulating properties, buildings are cleaner and homes are more energy efficient. They’re also less likely to burn out or be blown over, which can be attractive to insurance companies.

According to information released in January, the 3D printers used for these tasks also require only one or two people to operate, which may be a key detail as the country faces a shortage of construction workers. Related Builders and Contractors.

Texas has also begun building affordable housing through 3D printing, with two startups in the state trying to reduce inventory and address climate change by using 3D printing technology to build homes in the central region of the state.